Overall layout design

1) Arrangement of battery modules

Impact: The utilization of the limited space inside the battery pack directly affects the internal temperature distribution, mechanical safety, and electrical safety.

For automotive-grade products, in principle, priority should be given to proven mature products; the types of modules should be reduced as much as possible (ideally, there should be only one type of module inside the battery pack), which is conducive to product design, supply of raw materials and parts, production and manufacturing, and after-sales replacement.

2) Arrangement of longitudinal and transverse beams of battery box

The fixed structure must be strong enough to support the large mass of the battery pack without displacement under high acceleration conditions.

Function: After installation and fixation, it is connected to the vehicle body to increase the bearing strength of the vehicle body.

Design: Determine the specific structure, material type and thickness of the longitudinal and transverse beams through force analysis and calculation.

Many current battery packs have removed the longitudinal and transverse beams, leaving only the front and rear beams that fix the module end plates.

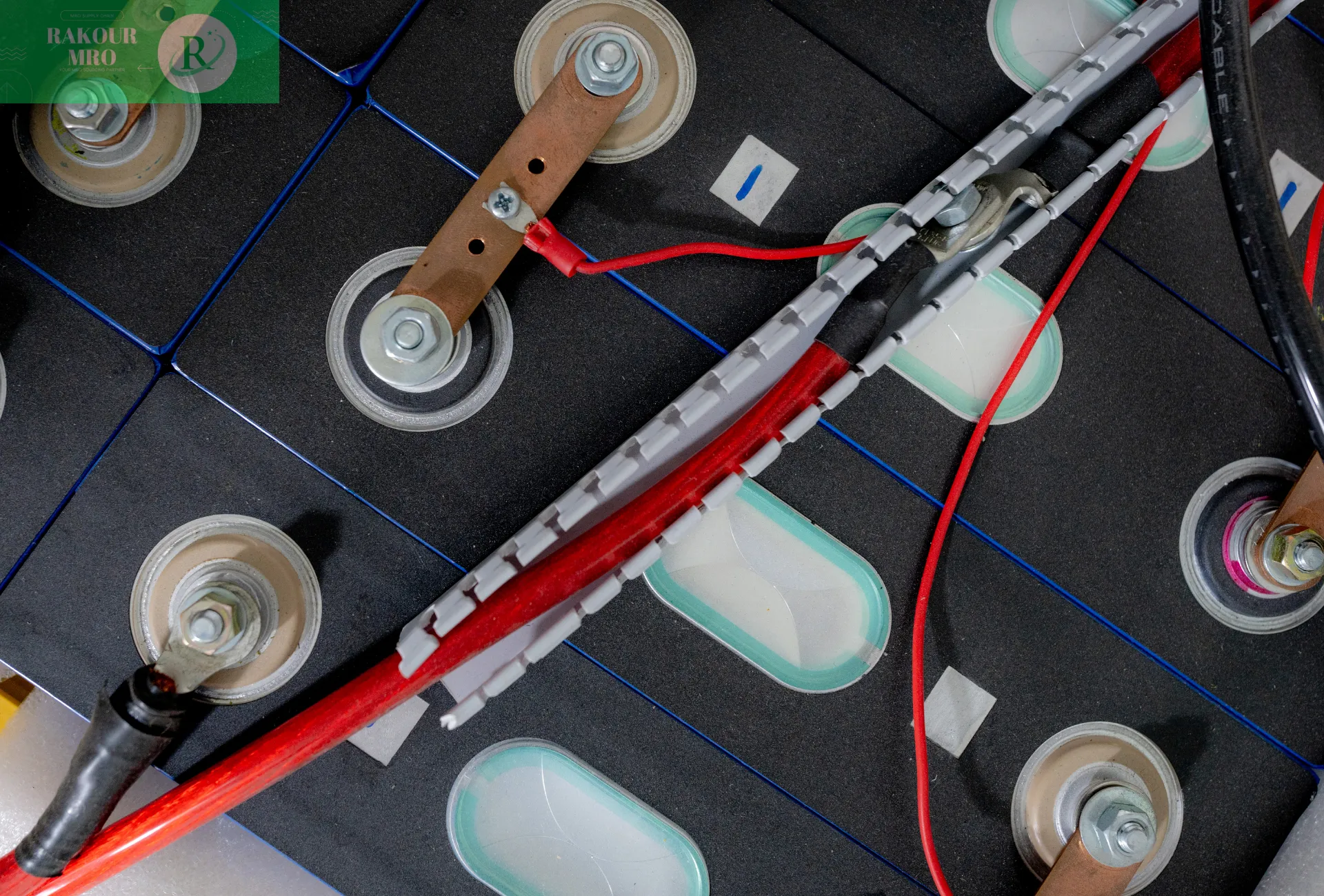

3) Arrangement of high and low voltage wiring harnesses

High and low voltage wiring harnesses should be arranged strictly separately to make full use of space; they should be fixed with wire clamps and meet electrical clearance requirements.

Layout principle: high pressure at low level, low pressure at high level; cross vertical layout is adopted when space is insufficient.

Box structure conceptual design

1) Battery box cover design

Function: The upper cover mainly plays a sealing role and is subject to less force.

Commonly used materials and processes: galvanized steel sheet (stamping, sheet metal bending and welding), aluminum alloy, composite materials (SMC, glass fiber reinforced composite materials, etc.)

2) Battery box sealing surface design

Sealing function and related design: The design of the sealing surface between the upper cover and the lower box body is very critical to the sealing performance, and needs to be designed in conjunction with the box structure and the sealing ring.

Flatness requirements: The sealing surface should be kept in the same plane as much as possible, and multi-curved surface structures should be avoided as much as possible.

Key points of bolt connection: Since the upper cover and the lower box body are connected by bolts and there are many bolts, it is very important to ensure the coaxiality of the holes and the flatness of the sealing flange surface. The bolt holes should be arranged reasonably, the size should be round and symmetrical in the X and Y directions. The number of bolts should be selected based on the sealing performance and the workload of disassembly and assembly.

3) Battery box lower box design

Function: The lower box is the carrier of the power battery system, and the battery module is arranged in it. It needs to be equipped with grooves, baffles and other structures inside to ensure that the battery module is reliably fixed in all directions when the vehicle is driving, to prevent movement and impact on the side walls and upper cover, which will affect the life of the box.

Manufacturing process selection: Aluminum profile welding technology can be used, high-strength steel is selected for the base plate and reinforced with stamped ribs, and X- and Y-axis "well"-shaped reinforcement beams are made at the connection points of the body to improve bending and torsional strength.

Materials and forming methods: The main materials and forming methods include bent profile sheet metal, stamped profile sheet metal, cast aluminum forming, welded extruded aluminum, etc. The selection is based on multiple factors such as batch size and production.

Module structure concept design

1) Mechanical strength design

Purpose: To ensure the structural integrity of the module under extreme working conditions such as collision, extrusion, and vibration.

The module assembly should be appropriately tight, and each structural component should have sufficient rigidity and strength to prevent deformation or damage due to changes in the battery's internal pressure. Modules should be as versatile and interchangeable as possible.

It is necessary to ensure that the battery cell does not move due to vibration

2) Thermal management and temperature control

Temperature monitoring: One NTC temperature sensor is placed every 2-5 battery cells; high temperature warning, for example, >60℃ triggers power reduction, >80℃ starts emergency cooling.

Thermal management: Based on the overall structural design requirements of the battery pack, the flow channel width and height are preliminarily determined. Through fluid simulation, the maximum temperature and maximum temperature difference of the battery cell are understood to ensure good heat exchange with the liquid cold plate.

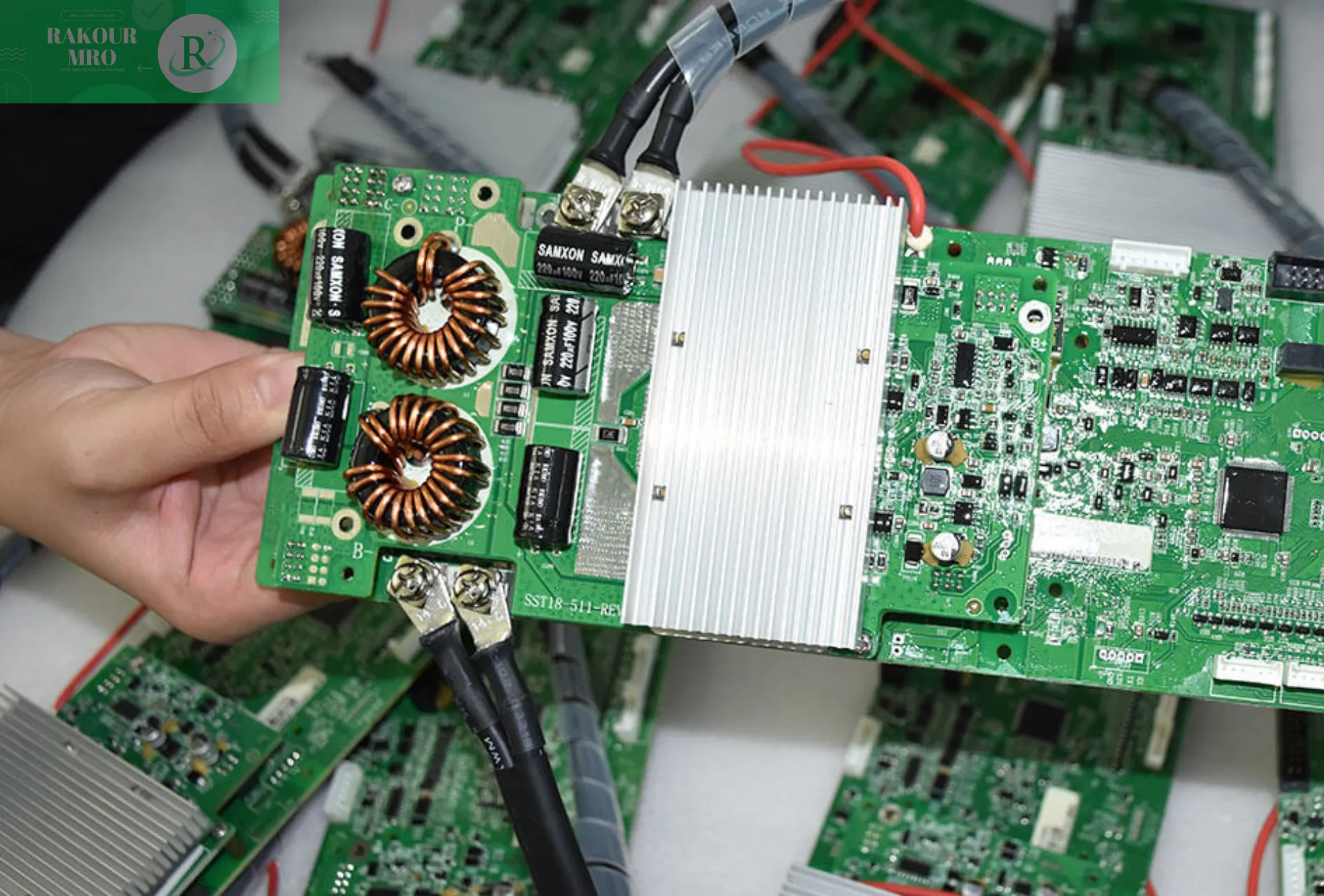

3) Electrical connection reliability

Check and verify electrical safety design: electrical clearance, creepage distance, contact protection, equipotential connection, etc.

The low-voltage wiring harness is reliably connected, with adequate anti-loosening and anti-fouling measures.