Main performance parameters of power battery pack

1) Rated voltage: The rated voltage and voltage application range of the power battery system must be matched with the high-voltage system components of electric vehicles such as motors and motor controllers.

2) Working voltage range: The working voltage range of the power battery system is mainly adapted to the upper and lower limit requirements of high-voltage components such as vehicle motors and motor controllers.

3) Total capacity: Discharge capacity requirements under specified conditions.

4) Total energy: The total energy/total power requirement that can be released when 100% SOC is fully discharged from 0% SOC in full electric state under specified conditions.

5) Available energy: The total energy/total power requirement that can be released when discharged from the upper limit of available SOC to the lower limit of SOC under specified conditions

The specified conditions refer to the specific temperature and discharge rate, such as 25°C, 1C discharge or 1/3C discharge.

6) Available SOC range: refers to the battery capacity range that can be safely used during normal operation. Corresponding to the available energy is the available SOC range, which is mainly limited by the application limitation of the single cell.

7) Peak discharge power: The maximum discharge power that can be provided under specified conditions within a specific time (generally not greater than 30s).

8) Peak charging power: the maximum charging power that can be provided under specified conditions within a specific time.

9) Lifespan: The cycle life is usually stipulated that the discharge capacity is less than 80% of the initial capacity as the lifespan end condition.

Analysis of parameter matching of power battery system

The improvement of electric vehicles’ battery life is not simply and roughly increasing the battery capacity, but requires a comprehensive project that systematically optimizes battery parameters, electric drive efficiency, thermal management and lightweighting of the entire vehicle.

For example, although the battery pack of Xiaomi YU7 standard version is only 96.3kWh, the battery life is 835km. Blindly increasing battery capacity will lead to a surge in costs, the weight of the vehicle will also increase, and it may also shorten battery life.

1) Rated voltage and voltage application range

For the rated voltage level of the power battery system of high-speed electric vehicles, refer to the “Voltage Level of High Voltage System of Electric Vehicles” (GB/T 31466-2015), 144V, 288V, 320V, 346V, 400V, 576V, etc. can be selected.

Currently, the most popular ones are 400V and 800V. The commonly referred to as 800V high-voltage platform refers to a range, which can generally be called 800V in the range of 550-930V. For example:

For the voltage level of the power battery system of micro low-speed electric vehicles (commonly known as Laotou Le), the voltage level below 100V is mainly 48V, 60V, 72V and 96V.

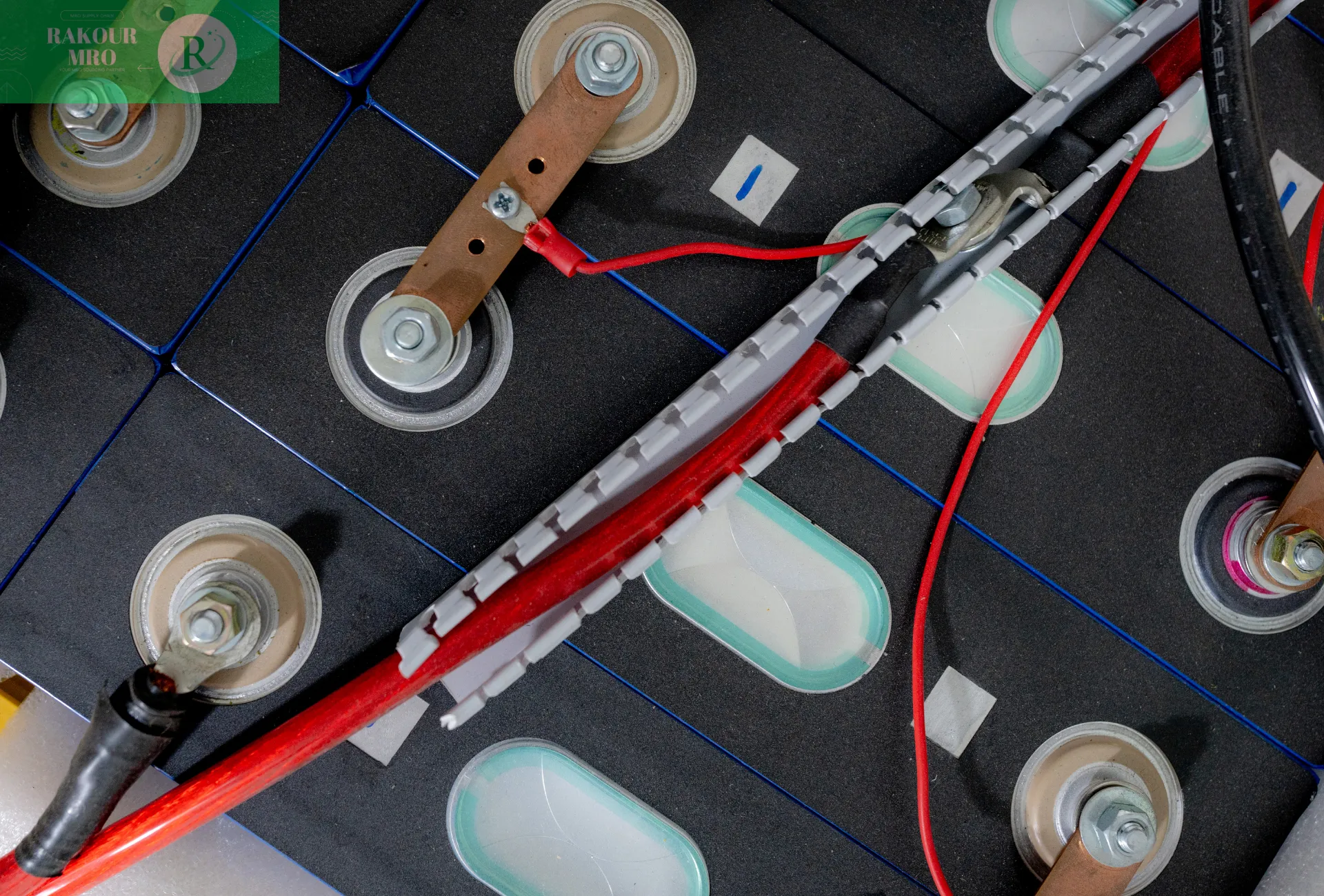

The rated voltage and voltage range of the power battery system must match the operating voltage of the motor and motor controller selected by the vehicle. Therefore, the appropriate single battery specification must be selected and the number of series and parallel connections must be determined, the system rated voltage and operating voltage range must be determined.

The rated voltage and voltage range of the power battery system must match the operating voltage of the motor and motor controller selected by the vehicle. Therefore, the appropriate single battery specification must be selected and the number of series and parallel connections must be determined, the system rated voltage and operating voltage range must be determined.

2)Power battery system capacity

In the concept design stage of the vehicle, starting from the weight and the typical working conditions of the vehicle, based on the requirements of the cruising range and vehicle performance (maximum speed, climbing slope, acceleration time, etc.), the total energy demand required for the vehicle form can be calculated.

The capacity of the power battery system is mainly calculated based on the total energy and the rated voltage.

3)Power and operating current

1. Peak power: During acute acceleration, the power battery system requires a short-term high current (the corresponding working current is the peak discharge current); during emergency braking, a short-term energy recovery is required (the corresponding feedback current is the peak charging current).

2. Continuous power: When driving on a flat road or on a long ramp, it is necessary to output a certain amount of current for a long time, mainly considering the internal resistance and temperature rise limit of the battery.

4)Available SOC Range

Typically, the SOC ranges from full-charged state (100% SOC) to fully discharged state (0% SOC), but in reality, the available SOC range of the power battery system is limited to a certain range for extended battery life and safety.

SOC window design principles:

Safety: Avoid overcharge (risk of lithium excretion) and overrelease (irreversible loss of active substances)

Lifetime optimization: shallow filling and light release (such as SOC = 20%~80%) can reduce capacity attenuation, but the range and cost need to be weighed.

Self-discharge compensation: When the storage period exceeds 3 months, the lower limit of SOC must be ≥5%, to prevent self-discharge from overdischarge.

Impact of SOC Available Range:

Design of total energy

Directly reflect: the selection and quantity requirements of single-cell batteries

It has the most direct impact on the size design, internal layout and installation space gap and overall cost of the battery box

To sum up, the selection of SOC usage intervals in the power battery system should comprehensively weigh the above influencing factors. Therefore, comprehensive balance selection is required to determine the best solution for the SOC usage interval.

5)Temperature application range

The temperature application range of power battery systems is mainly considered:

Effects on the charging, discharging power and energy of a single battery under low temperature conditions;

Effects on battery life and safety characteristics under high temperature conditions.

1) Operating temperature range

Generally speaking, the power battery system is required to work normally at an external ambient temperature of -20~60℃.

2) Storage temperature range

Under general conditions, power battery system products are required to be able to be stored within the range of -40 to 60℃.