Its main functions include:

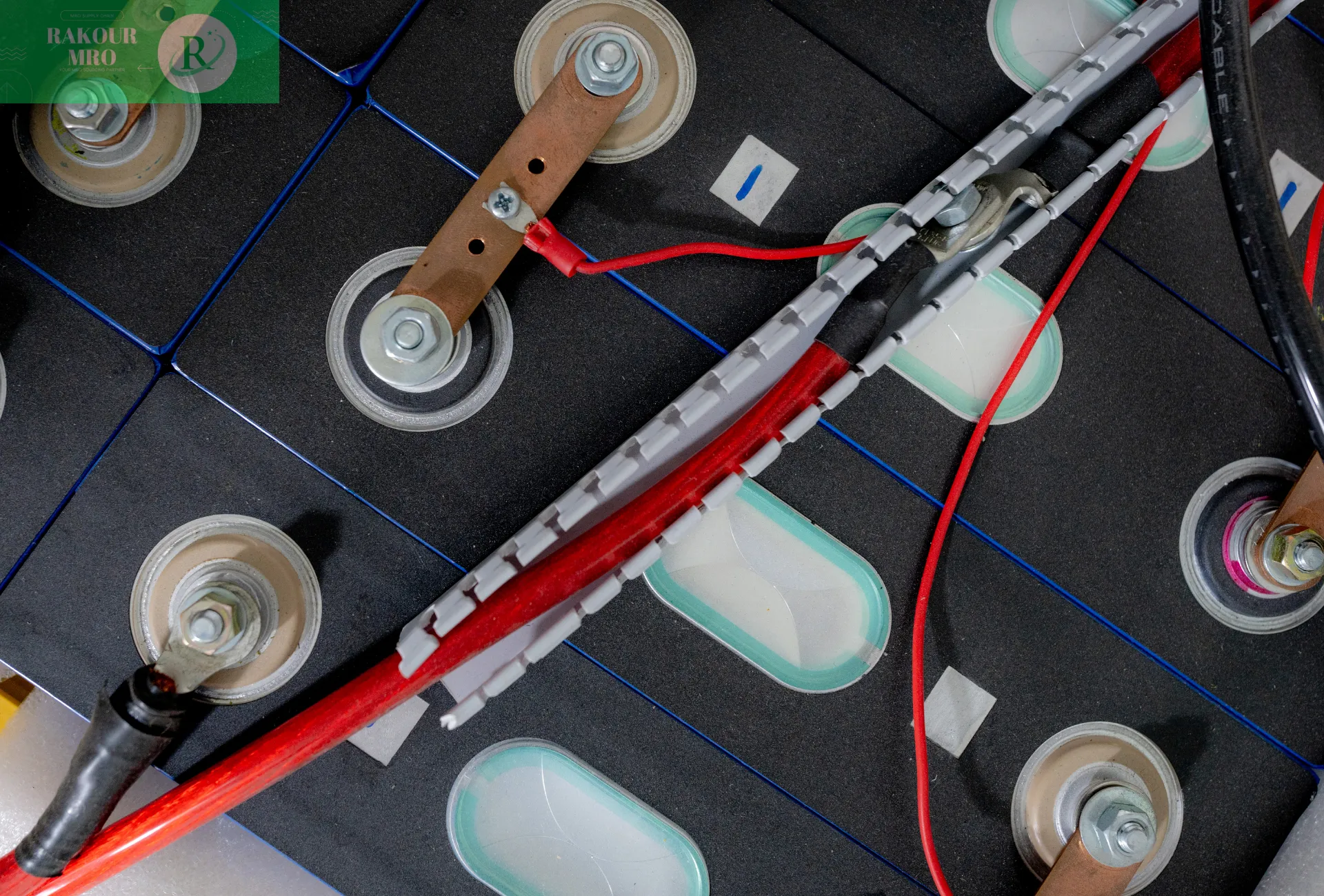

1. Status monitoring: Real-time collection of battery voltage, current, temperature and other parameters, and calculation of key indicators such as state of charge (SOC) and state of health (SOH).

2. Safety protection: Prevent abnormal conditions such as overcharging, over-discharging, overheating, and short circuit, and achieve multi-level protection through hardware protection circuits and software algorithms.

3. Balancing management: Through active or passive balancing technology, the capacity difference between single cells is reduced and the overall life is extended.

4. Communication and control: Interact with vehicles or external devices through CAN, LIN and other protocols to execute charging and discharging strategies and upload data.

BMS Architecture Classification

1) Centralized BMS

The centralized BMS mainly consists of an all-in-one machine and a high-voltage switch box, which concentrates the functions of the BMS in a single controller and realizes functional integration through the division of high-voltage and low-voltage areas.

Advantage:

1. Low cost: At the hardware level, the slave does not require a controller, which simplifies the architecture and reduces costs.

2. Compact structure: suitable for space-constrained scenarios (such as power tools, portable devices)

Shortcoming:

1. Low reliability: Single point failure may cause system paralysis

2. Poor scalability: When the number of sampling channels increases, the wiring becomes complicated and the EMC risk is high.

Applicable scenarios: scenarios with low capacity, low total voltage, and small battery system size (low complexity)

2) Distributed BMS

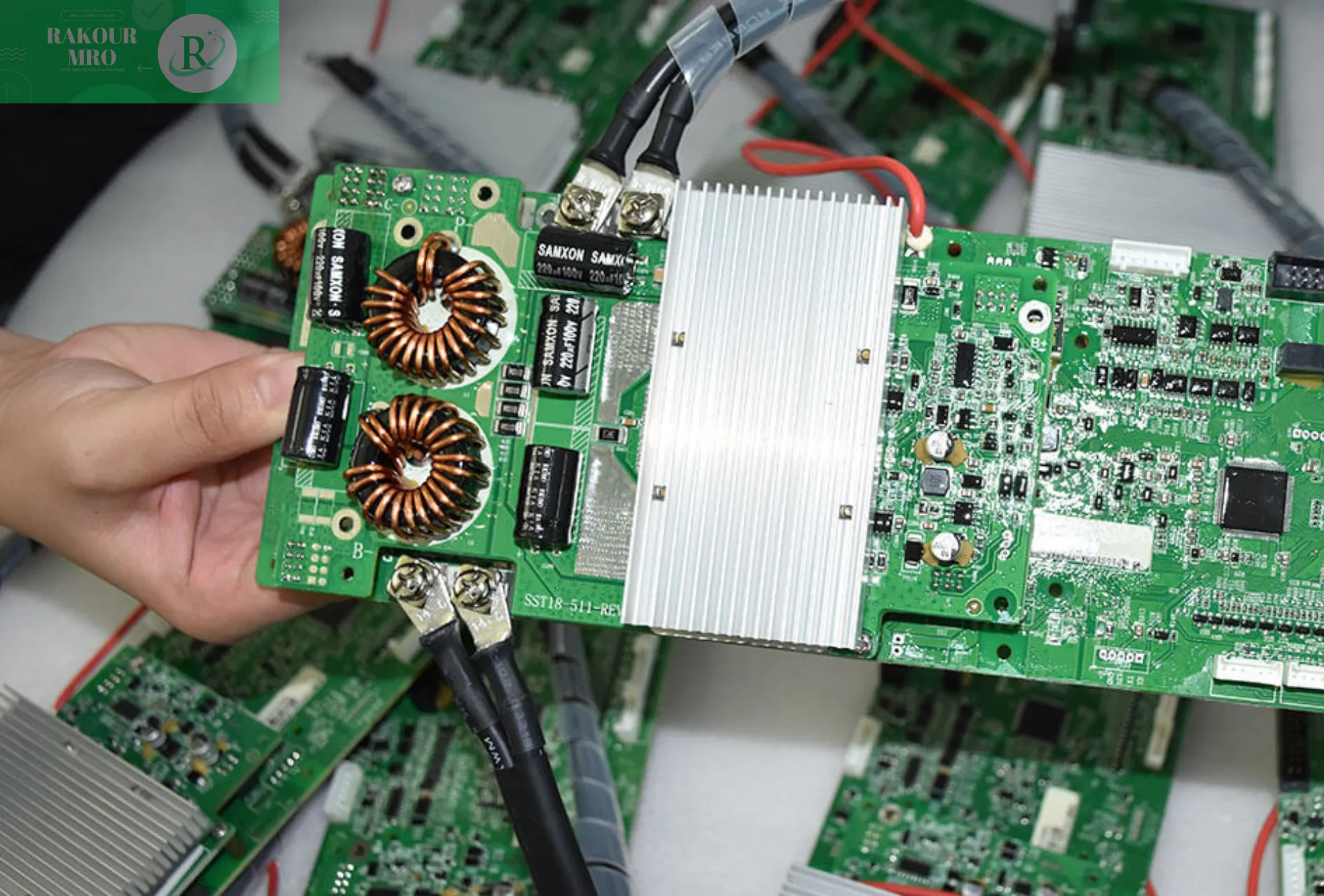

Distributed BMS distributes functions to multiple sub-modules (such as slave control unit CSC and master control unit BMU). Each module independently completes local data collection and preliminary processing, and achieves collaboration through bus or chain communication.

Mainstream BMS products in China all have a distributed architecture, generally divided into a master and slave units. Functionally, the slave unit is responsible for collecting the voltage and temperature of the battery cells and transmitting them to the master unit via the CAN bus. The master unit is responsible for calculation, protection, and control.

Slave control module: single cell voltage/temperature detection, balancing management, fault diagnosis

Main control module: system evaluation, electrical system status detection, contactor management, thermal management, operation management, charging management, diagnostic management, and management of internal and external communication networks

Advantage:

1. High reliability: Modular design, single point failure does not affect the overall situation (e.g. CSC failure can be isolated)

2. Good scalability: supports dynamic addition and removal of modules (such as energy storage system expansion)

Shortcoming:

1. High cost: multiple controllers and communication modules are required

2. Strong communication dependence: bus failure may cause data loss

Applicable scenarios: Mainstream production electric vehicles generally adopt distributed architecture. Industrial and commercial storage and large storage mostly adopt distributed architecture due to the large number of battery cells and complex structure.