Lithium battery module expansion phenomenon

Lithium batteries are often described as “rocking chair batteries,” meaning that lithium ions migrate back and forth between the positive and negative electrodes driven by a potential difference, storing and releasing electrical energy.

However, the process of Li+ intercalation and deintercalation in the positive and negative electrode materials causes the active material to expand in volume. This expansion can be reversible or irreversible, and irreversible expansion accumulates with the number of charge and discharge cycles in lithium-ion batteries.

Battery cell expansion is primarily caused by three factors: electrochemical expansion, gassing expansion, and temperature effects.

Epoxy sheets are often used as a buffer material between lead-acid batteries in two-wheeled electric vehicles. However, epoxy sheets are brittle and lack resilience, making them incapable of absorbing the cell expansion force. Therefore, they are unsuitable as a buffer material for lithium-ion battery packs, despite their very low price.

Compared to carbon anodes, lithium-ion batteries with silicon anodes have significantly higher energy density, offering an effective way to further increase battery energy density. However, their significant expansion rate (thickness increases by 15%-30% after 100 cycles) has hindered their practical application.

Main types of cushioning materials

Since cell expansion is an inherent phenomenon during the battery’s lifecycle, minimizing its negative effects is crucial to extending battery life.

If irreversible cell expansion is not effectively mitigated, it will further accelerate the cell’s lifespan degradation.

The following patterns apply to lithium-ion cell expansion:

1) Spatial distribution: The expansion force in the center is greater than at the edges.

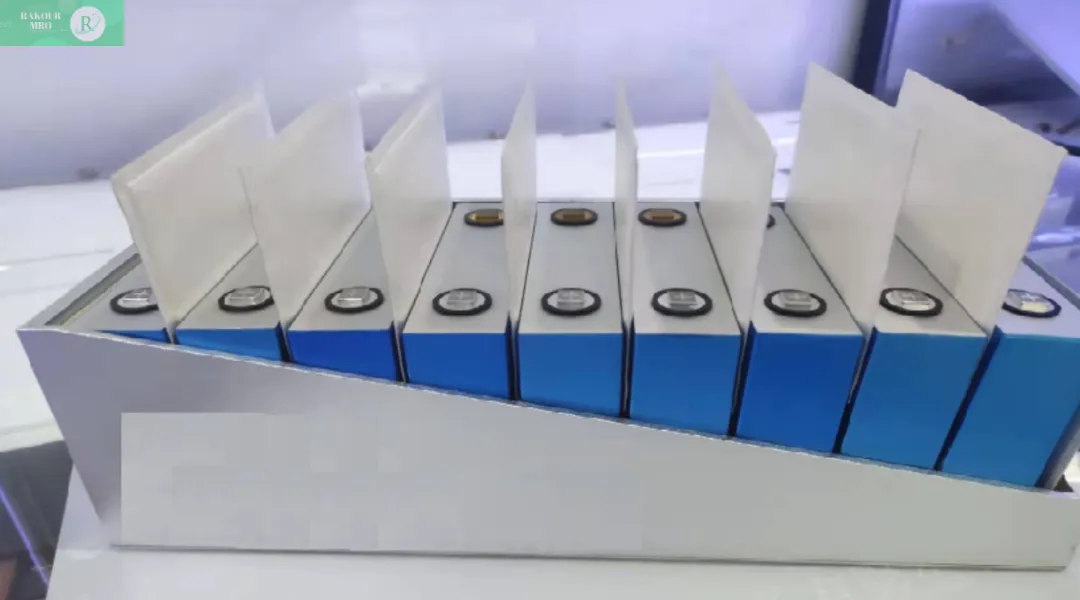

2) Capacity: The greater the cell capacity, the greater the expansion rate (energy storage cells tend to have large capacities).

3) Cell type: Ternary cells have a greater expansion rate than lithium iron phosphate cells (NCM811 cells can expand by 6-8%, while LFP cells only expand by 3-5%).

In fact, the higher the energy density of the battery, the greater the expansion rate

4) Cycle Number: As the number of charge and discharge cycles increases, irreversible expansion accumulates, and the cell expands further.

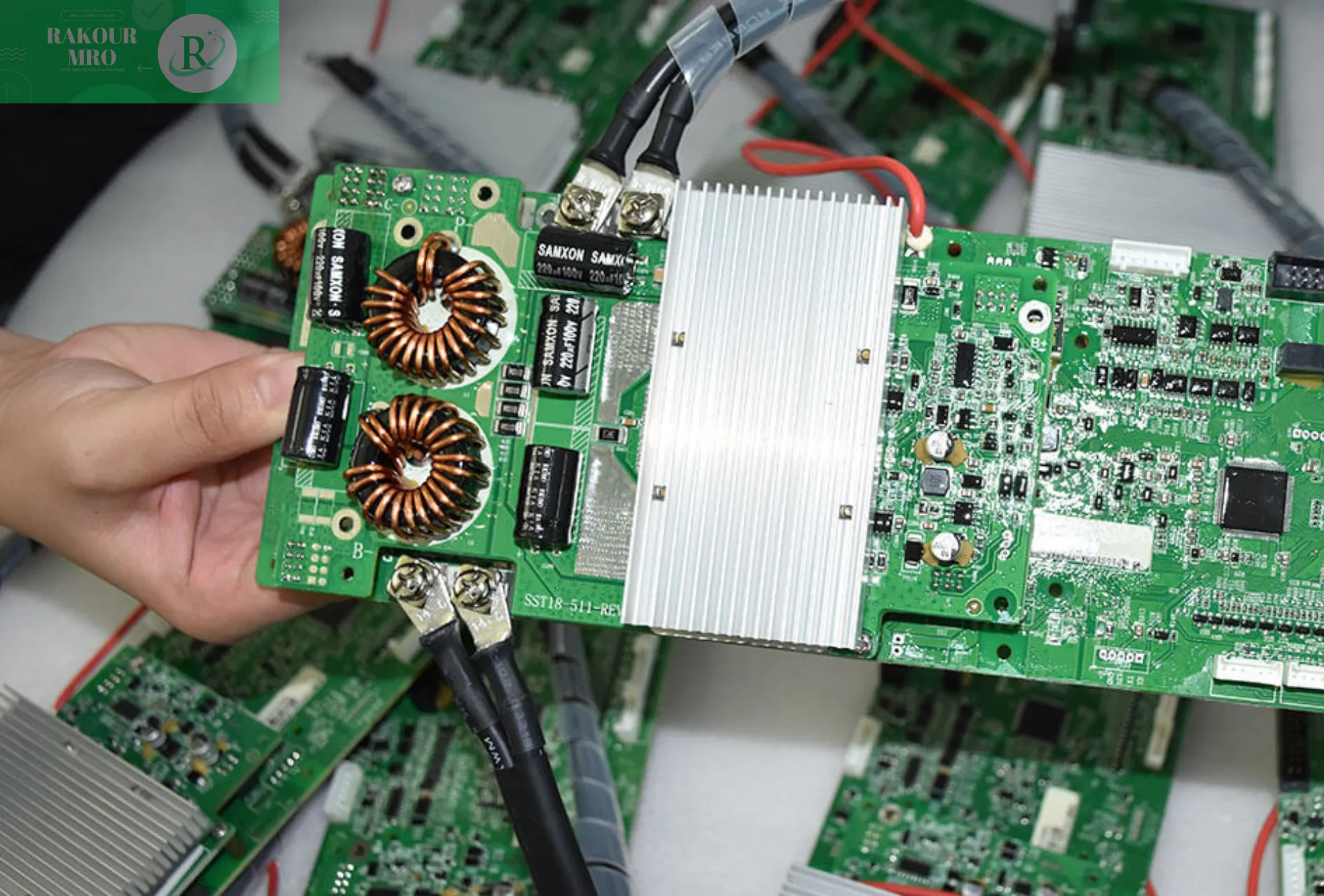

Therefore, cushioning materials are essential to the module. Their main functions include pressure distribution, displacement compensation, and thermal insulation and flame retardancy.

Silicone foam

The density of the silicone foam base is 1.17 g/cm³. After foaming, the density is approximately 0.16-0.20 g/cm³. Its vertical flame retardancy can reach UL94-V0 and has low compression set. Silicone foam is particularly recommended as a cushioning material for larger energy storage battery modules (which experience greater expansion forces).

EVA foam

EVA foam is actually quite common in everyday life—it's used in the soles of slippers. Those who have owned these slippers may already be aware of its drawbacks: the heels can become permanently flattened after prolonged use, which also indicates that EVA has a high compression set.

EVA is inexpensive and is primarily used between prismatic battery cell modules.

CR foam

CR foam, short for chloroprene rubber foam, is UL94V-0 flame retardant certified and RoHS compliant.

Features: Low density, lightweight, low hardness, high compression, excellent thermal insulation and flame retardancy, excellent resilience, and a long service life.

PU

PU refers to a copolymer of polyurea/modified polyurethane, characterized by numerous micropores and polyurethane resin walls. PU has slightly poor compression resilience and is primarily used between soft-pack battery modules.

Features: Porosity, low density, and high specific strength. It exhibits high rebound and air permeability, low hysteresis loss, a high compression-to-load ratio, and excellent flame resistance, as well as resistance to heat aging, humidity aging, and dynamic fatigue.

MPP

MPP is a porous foam material made by creating a large number of micron-sized bubbles within polypropylene (PP) using clean supercritical carbon dioxide technology. MPP complies with RoHS and REACH requirements and is widely used in the new energy sector.

Features: Lightweight, high strength, efficient impact energy absorption, excellent flame retardancy, and heat resistance.

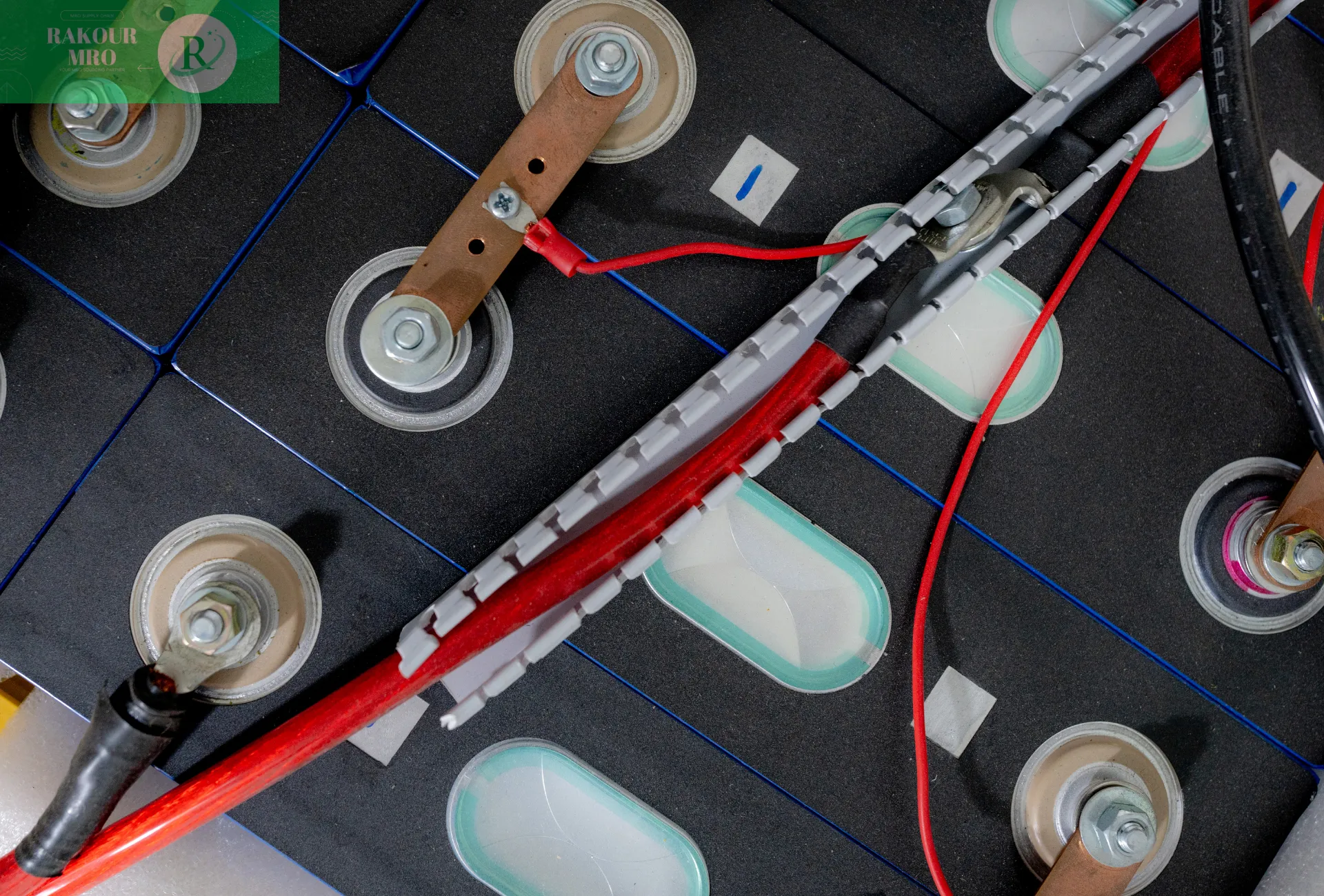

Aerogel

The elastic materials discussed above primarily absorb the expansion force of battery cells. Aerogel is another commonly used material between battery cells. Its primary function is thermal insulation and flame retardancy, but aerogel also exhibits excellent compression properties, providing a certain cushioning effect.

For example, in a 1P13S module, under a load of approximately 200 kgf, a 2.0 mm thick layer of aerogel compresses to approximately 1.5 mm.

Aerogel insulation sheet is a composite insulation material made from silica aerogel and a ceramic fiber matrix. It features low density, high porosity, high-temperature resistance, and low thermal conductivity, effectively preventing heat transfer between battery cells during thermal runaway.

Summarize

| Material Abbreviation | Material Name | Application |

|---|---|---|

| EVA | Ethylene-Vinyl Acetate Copolymer | Used between prismatic battery cells, low cost. |

| PU | Polyurethane | Typically used between pouch battery cells. |

| / | Silicone Foam | Used between prismatic battery cells, with good aging resistance and compression resilience. |

| CR | Neoprene Rubber Foam | Good compression non-resilience, used for waterproofing and insulation isolation. |

| MPP | Polypropylene | Used between prismatic battery cells, low cost. |